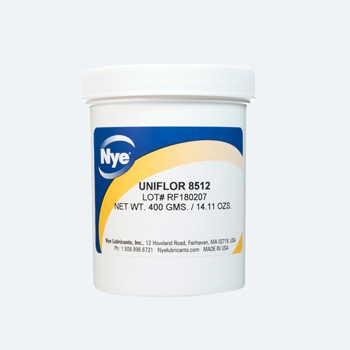

Uniflor (PFPE Lubricants)

Information guide

Nye Lubricant® brand Uniflor™ PFPEs are the most thermo-oxidatively stable lubricants available today. Unlike any other brand of fluorinated lubricants, the Uniflor™ line utilizes every PFPE oil available to create a diverse product line and achieve optimal performance under a variety of operating conditions. Uniflor™ products can withstand temperatures ranging from -90°C to +250°C, and even higher excursions.

What are PFPEs?

Perfluoropolyethers (PFPEs) are synthetic fluorinated fluids that are well suited for demanding environments or applications where chemical interaction between materials may be an issue. Although all PFPEs are composed of carbon, fluorine and oxygen, the molecular structure of each PFPE fluid varies depending on the base materials and polymerization processes used by PFPE manufacturers. These structural differences affect the fluid's pour point, volatility, viscosity and viscosity index - all critical factors in lubricant formulation. Some PFPE oils, for example, have a pour point of only -20°C, while others offer pour points as low as -90°C. Similarly, some PFPE oils offer better wear resistance and vapor pressure properties than others.

Advantages of Uniflor™ PFPEs :

- Wide temperature performance

- Excellent oxidative and thermal stability

- Resistant to aggressive chemicals and solvents

- Non-flammable and chemically inert

- Low volatility and vapor pressure

- Excellent compatibility with plastics and elastomers.

Uniflor™ lubricants for your industry :

Below is a selection of our most commonly recommended Uniflor™ products by industry.

Automotive :

To produce more powerful and efficient vehicles, automotive lubricants must be compatible with a range of materials while withstanding high temperatures. Uniflor™ lubricants are compatible with most plastics and elastomers and have been designed to resist harsh chemicals such as brake fluid and exhaust fumes. PFPE's high-temperature stability helps protect against wear and arcing conditions to extend service life.

- Anti-lock brake bearings and pistons

- EGR Valves

- Sensors

- Switches

Aeronautics:

Primary flight controls must activate properly as desired by the pilot when the aircraft is in flight. Lubricating the airframe components with a grease designed for high-speed, high-temperature conditions will ensure the long-term, maintenance-free operation of these critical flight systems. Similarly, engine components, including the lubricant, must withstand a wide range of temperatures, be compatible with the fuels used in aviation, and resist corrosive fuel system vapors. Below are some examples of areas where UNIFLOR greases are used:

- Flight controls

- Fuel systems

- Electrical systems

- Cabin mechanisms

Defense:

The thrust vector allows jets to direct engine power for maximum maneuverability, short takeoffs and landings. The actuator physically redirects the jet's propulsion, which requires a lubricant that survives the hot engine exhaust. Uniflor™ greases are well suited for defense applications because they are resistant to hydrocarbon fuel and liquid oxygen.

Medical:

Medical lubricants are often selected to prevent wear and/or seal applications against fluids and debris that could harm patients. Uniflor™ lubricants resist chemicals to protect your components and minimize risk. In addition, their resistance to wide temperature ranges makes Unifor™ the ideal choice for high-temperature motorized applications. For medical systems where proximity to patients raises concerns about bio-compatibility, the NyeMed® product line includes PFPE formulations that have been tested and certified.

_1673427121.png)