Sputtering targets for thin film deposition

(Discover our sputtering targets)

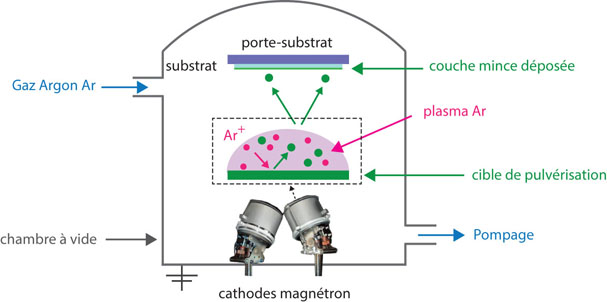

The principle of sputtering is to use the plasma energy (partially ionized gas) on the target surface (cathode) to extract one by one the atoms of the material and to bring them on the substrate (refer to the drawing below).

In order to achieve this deposition we create a plasma by ionization of a pure gas (usually Argon) thanks to a voltage difference (DC or pulsed DC), or an electromagnetic excitation (MF, RF); this plasma is composed of Ar+ ions which are accelerated and confined around the target thanks to the presence of a magnetic field. Each ionized atom, by striking the target, transfers its energy and rips off an atom; this atom have then enough energy to be projected to the substrate.

The plasma is created in elevated pressure (10-1/10-3 mbar), but it is necessary to start with a lower pressure before introducing Argon, to avoid any contamination due to residual gases in the chamber.

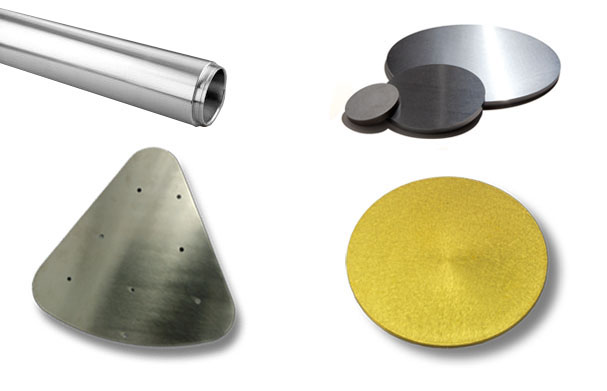

Advantages: the diversity of sputtering targets shapes (circular, rectangular, delta, tubular,…) and the use of various materials allow to create all kinds of thin films, even alloys within the same run.

Sputtering offers good adherence and can be used in roll-to-roll deposition.

_1673427121.png)